wire edm machine is an electro process

Sanırım bunun feriştahı bizim okulda yaşanmıştır. Worker Adjustment and Retraining Notification WARN Notice Table.

Electrical Discharge Machine Sinker Edm And Wire Edm

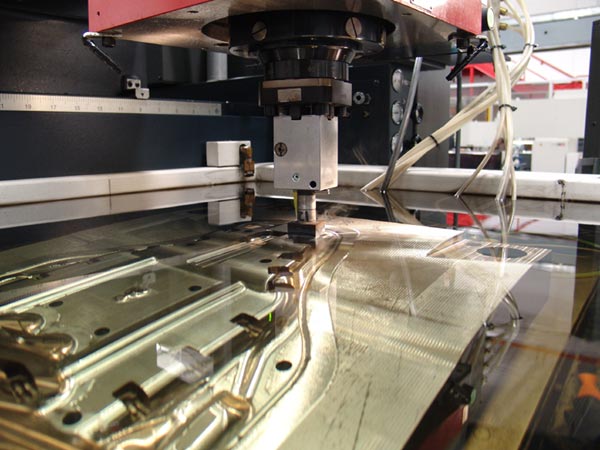

Wire EDM in process Wire EDM machine.

. A thin strand of metal wire accompanied by deionized water allows the wire to cut through metal just from the heat of the sparks. Concrete music is a type of music composition that utilizes recorded sounds as raw material. If you have any.

A wire EDM machine is a type of CNC machine that can move along four independent axes to. A wire EDM machine works in a similar way to a cheese cutter or a bandsaw cutting wood although the wire moves rather than the workpiece. The table allows you to search through the table search files sort columns view up to 100 entries at a time and export the data in the table.

Program CNC wire cut machines. It takes the form of a laminated sandwich structure of conductive and insulating layers. CNC turning milling conventional machining and wire EDM capabilities contact Small Parts Manufacturing today at 503 287-1181.

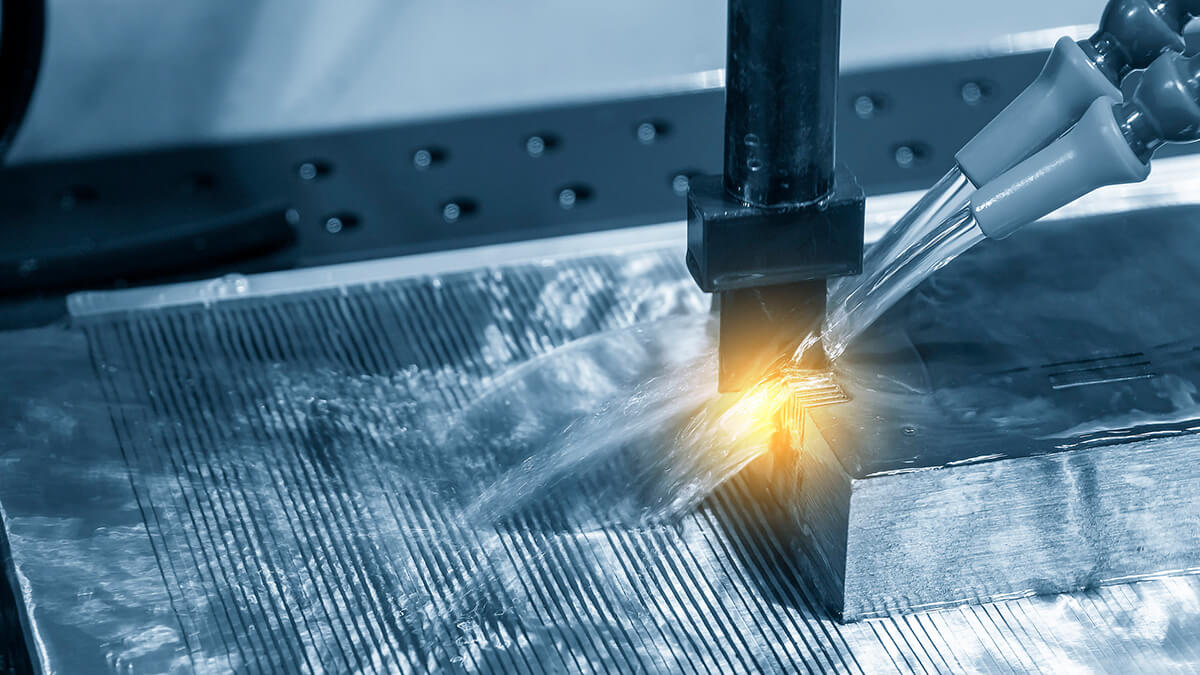

Electrical discharge machining EDM also known as spark machining spark eroding die sinking wire burning or wire erosion is a metal fabrication process whereby a desired shape is obtained by using electrical discharges sparks. A metallic wire usually brass or copper has high voltage electrical discharges passed through it that allows it to cut through the entire thickness of the material. Wrightcut EDM Specializes in Die and Mold components high taper applications and production solutions.

Please help improve this section by adding citations to reliable sources. Every branch of the military requires a constant stream of high-quality components for both new equipment and replacement parts for frequently used. Okul bahçesinde maç yapılıyor.

Companies like Milco Wire EDM as well as Owens Industries Inc. MEM07022C - Program CNC wire cut machines. Electrical discharge machining EDM is a popular nonconventional machining approach that is often used on hard materials.

By Ben Rogerson published 5 September 22. Drill EDM machine. HS-ADS07 series welding machine also uses our companys own high-frequency inverter technology compared with the traditional machine small size light weight high conversion efficiency energy saving and energy saving and imported machine the price is cheap the power grid adaptability is strong What is outstanding is the use of twice inverter1.

MacアドレスはIEEEで管理されていて最新のデータは下記より取得可能です テキストファイル IEEEウェブサイトSearch the Public MA-L Listingから検索することが可能ですMAC ベンダー0. Another area in which Wire EDM is used is in the military. Are supporting the military through CNC manufacturing specifically Wire EDM.

Jahan in Micro Electro-Fabrication 2021. Make room for EDMs new one-stop synth sampler rompler hybrid. This method is popular because of the fact that EDM can machine any materials irrespective of its hardness.

Ne yazık ki o maçta kayahan efsane goller yiyor maç farklı bitiyor. Perform advanced machineprocess operation. Sounds are often modified through the application of audio signal processing and tape music techniques and may be assembled into a form of montageIt can feature sounds derived from recordings of musical instruments the human.

Also printed wiring board or PWB is a medium used in electrical and electronic engineering to connect electronic components to one another in a controlled manner. Modalics is offering you a deep-pan programming experience. Drum and bass commonly abbreviated to DnB DB Drum n Bass and Drum Bass is an electronic music genre that originated in the UK rave scene having developed from breakbeat hardcore and its derivatives of darkcore and hardcore jungleThe genre would go on to become one of the most popular genres of electronic dance music becoming international and.

Electropolishing as a Secondary Finishing Process. A thermal oxidizer blends several. Electro Pneumatic Valves Control Valves for Augmentation of SCFT Facility.

Operate and monitor machineprocess. Definition of Electro Discharge Machining. This is also known as electro-discharge erosion.

Efenim olay şöyle oluyor. Wire EDM is an electro-thermal manufacturing process where components are made using electrical discharges. Perform electro-discharge EDM machining operations.

Unsourced material may be challenged and removed. Electronic music is a genre of music that employs electronic musical instruments digital instruments or circuitry-based music technology in its creation. Process development and supply of Inconel 718 supportless LPBF processed spherical gas bottle.

Material is removed from the work piece by a series of rapidly recurring current discharges between two electrodes separated by a dielectric. Electrical Discharge machining is the process of metal removal from the work surface due to an erosion of metal caused by electric spark discharge between the two electrodes tool cathode and the work Anode. Our team of skilled and tenured craftsmen is ready to work with you to design and manufacture the parts you need at a competitive price with uncompromising quality.

An Electro Discharge Machine consists of. Set computer controlled machinesprocesses. Adjunct membership is for researchers employed by other institutions who collaborate with IDM Members to the extent that some of their own staff andor postgraduate students may work within the IDM.

The electropolishing process does have limitations. Parts of Electro Discharge Machining. December 2009 Learn how and when to remove this template message This tree lists various manufacturing processes arranged by similarity of function.

Saha kenarında ki kızlar da başlarına geleceği bilmeden hop. Neyse bu lise 3 sınıfının kalesinde olayımızın kahramını kayahan bulunuyor. Use the table below to find the most recent WARN notices all the way back to 2008.

In the 1940s two Soviet researchers the Lazarenkos developed a machining process that formed the foundation for modern wire EDM and small hole EDM. It includes both music made using electronic and electromechanical means electroacoustic musicPure electronic instruments depended entirely on circuitry-based sound generation for instance using devices such as an. Thus the process is best applied to micro burrs or those that protrude less than about 00015 from the part surface.

This section does not cite any sources. For 3-year terms which are renewable. An EDM Wire-cut machine uses a continuous thin electrically conductive wire as the electrode to cut profiles on the workpiece and this process is called wire cutting.

Yamulmuyorsam bir taraf lise 3 bir taraf lise 2. Asif Rashid Muhammad P. A printed circuit board PCB.

Each of the conductive layers is designed with an artwork pattern of traces planes and other. A basic introduction to the wire EDM process. The wire and the workpiece are submerged in a dielectric fluid and sparking takes place in the spark gap between the wire and the workpiece surface.

Meet Beat Scholar the new rhythmic pizza plugin that wants a slice of the drum machine pie. This page was last updated on August 12 2022. The Institute comprises 33 Full and 13 Associate Members with 12 Affiliate Members from departments within the University of Cape Town and 12 Adjunct Members based nationally or internationally.

The longer the electrical current is applied the more material is removed but the less uniform the resulting surface finish.

Wire Electrical Discharge Machining An Overview Sciencedirect Topics

Wire Edm Machining For Extreme Accuracy Explained Mellowpine

A Japax Ldm 50 Wire Edm Machine B Schematic Diagram Of Wire Edm Process Download Scientific Diagram

Wire Edm Cutting Vs Laser Cutters

Rule Based Dfm Analysis For Electric Discharge Machining Wikipedia

Schematic Diagram Of A Wire Edm Machine Download Scientific Diagram

Wire Edm Guide To Edm Wirecut Machine Process Uses Fine Metalworking

Wire Erosion Machines Chmer And Ams Tech Edm Plus

Wire Edm Machining Sprutcam 14 All Lang User Manual

Wire Edm Find Suppliers Processes Material

Wire Edm Find Suppliers Processes Material

The Wire Edm Machine Cutting The Die Parts With Liquid Coolant Stock Image Image Of Metalwork Discharge 169298797

Wire Edm Introduction As We Build Our Knowledge Database We By Factorem Medium

Wire Cut Edm Process 2 Download Scientific Diagram

Pros And Cons Of Edm What Is Electrical Discharge Machining And How Does It Work Edi Weekly Engineered Design Insider

Mas 865 How To Make Something That Makes Almost Anything

Three Common Types Of Electrical Discharge Machining Market Prospects